The new flywheel bolts finally arrived so it’s time to start putting stuff back together.

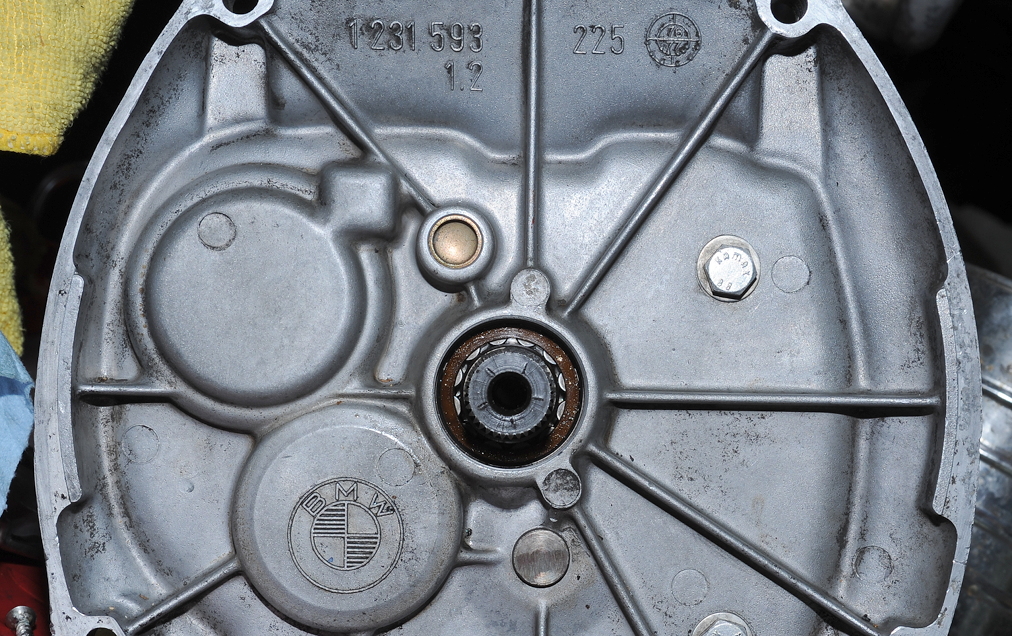

I started by installing the oil pump cover, using medium blue Loctite on the bolts. I then installed the flywheel and torqued the bolts to 77 ft-lbs.

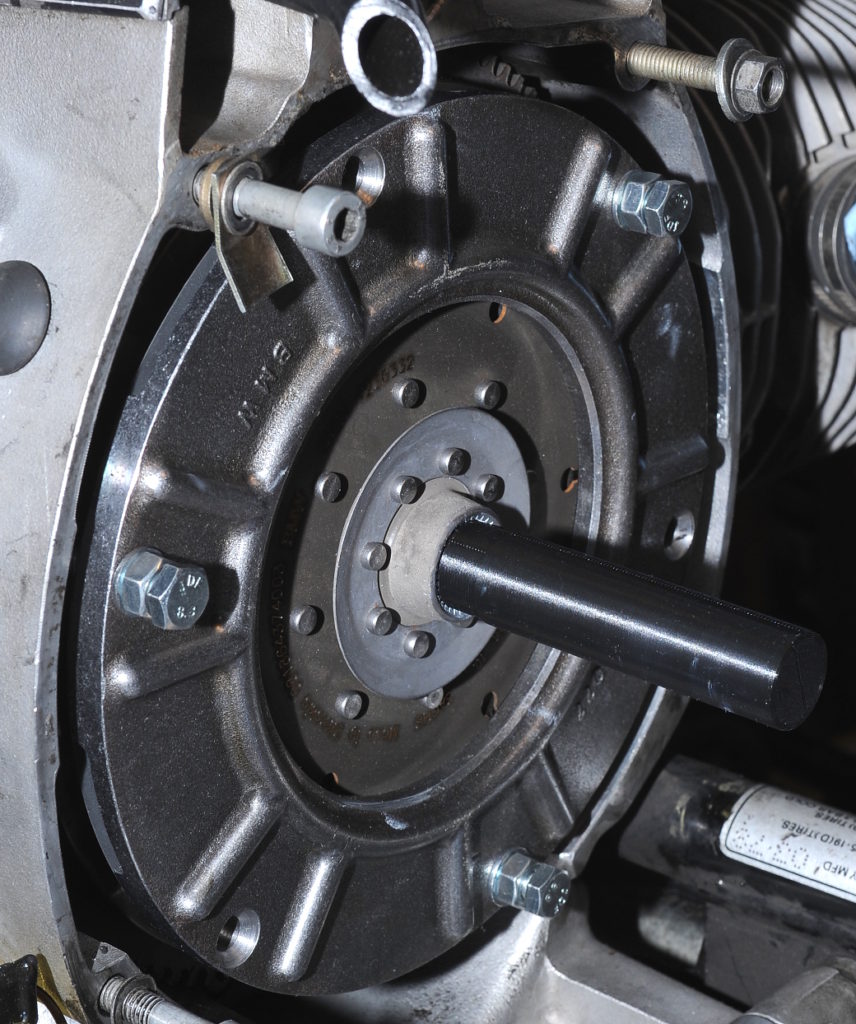

The clutch spring was lightly lubricated with Staburags NBU30PTM grease around the outer edge and on the ends of the fingers. Here you can see my 3D printed clutch tool being used to align the disk. There’s not a lot of pressure as the three temporary long bolts are holding the assembly in place, so it’s easy to move the disk into alignment.

I couldn’t find any balance marks, so I assumed the parts had been dynamically balanced at the factory.

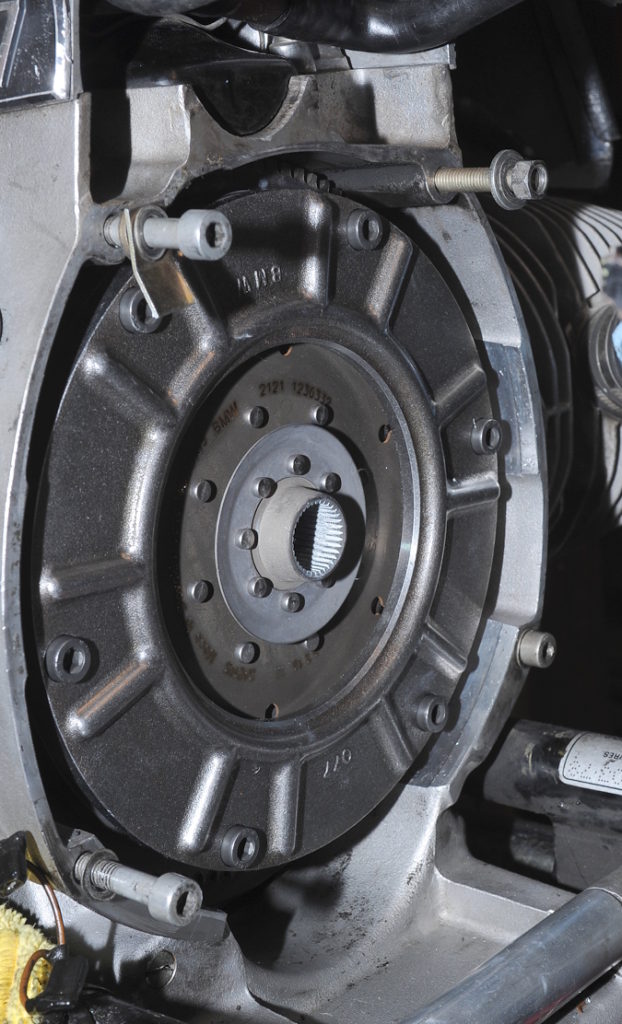

With the disk aligned I fully compressed the spring using the nuts on the long bolts and then installed the new clutch bolts torqued to 210 in-lb (17 ft-lbs). You can also see the light coating of (white) Staburags grease I used on the splines. Looks better than before!

Looks better than before!

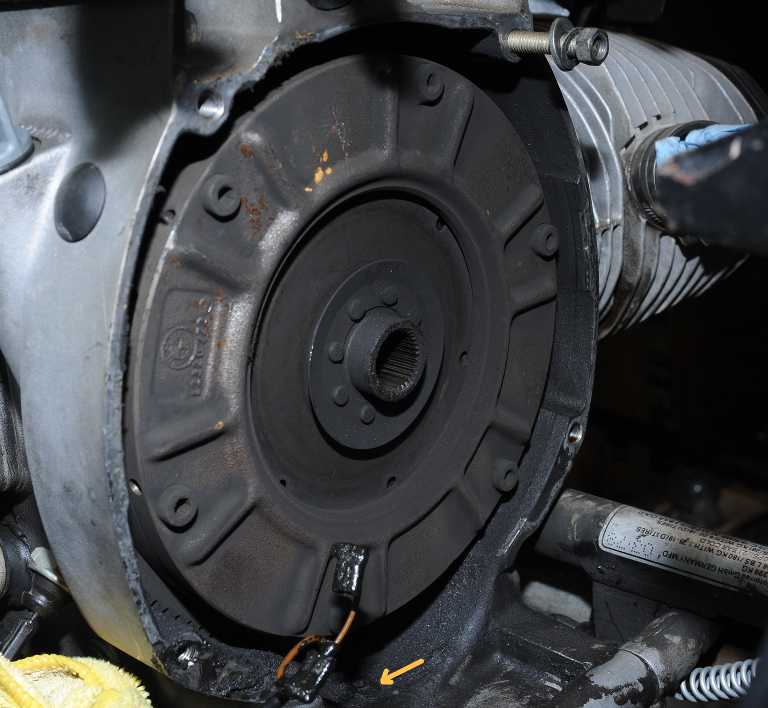

I also removed the transmission input shaft seal. It was a real pain to get out, and it didn’t come out in one piece. In this picture you can see the roller bearings around the input shaft. Tomorrow I’ll install the new seal.