To properly repair the center stand I have to remove the exhaust headers. That requires a special wrench which just came in the mail. I bought this one on eBay. It’s not steel, but looks strong enough to do the job.

The tool is fine, but even with a large rubber mallet the nuts weren’t budging.

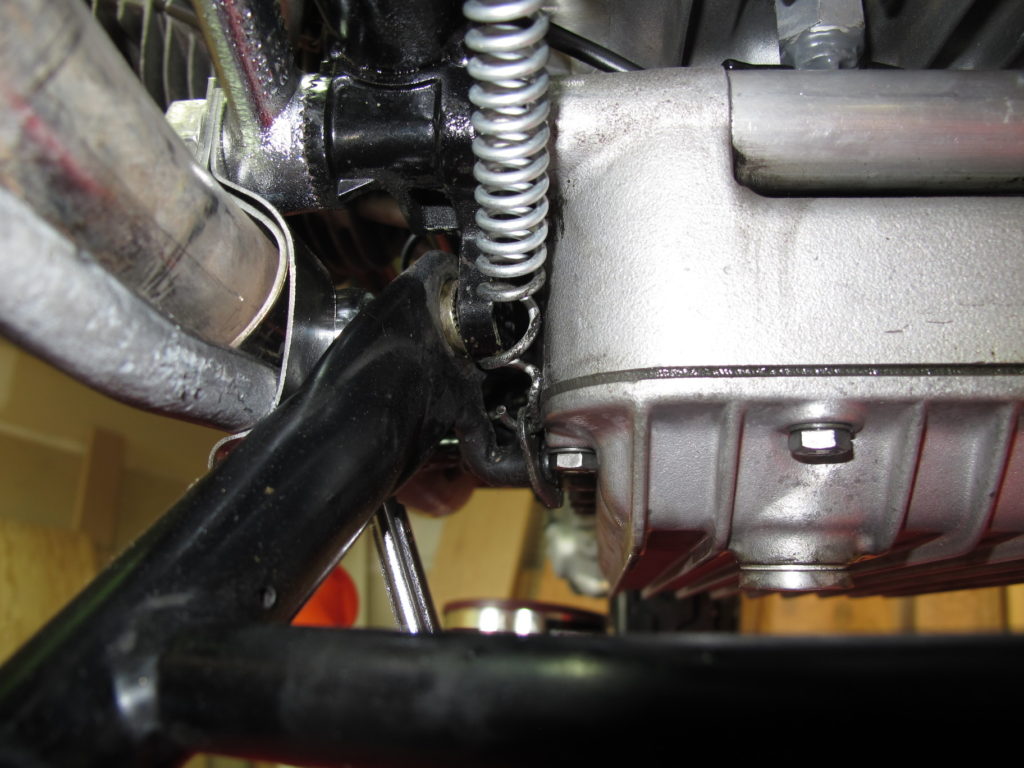

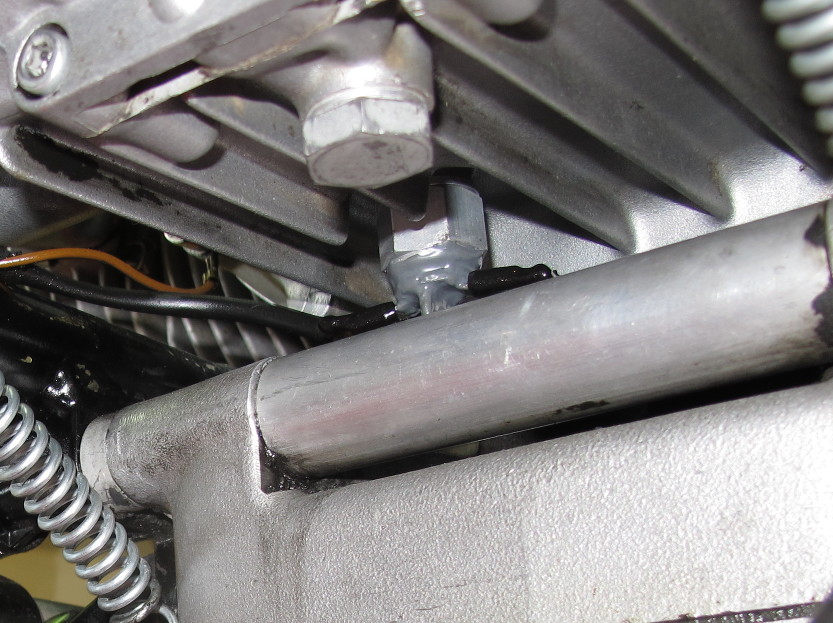

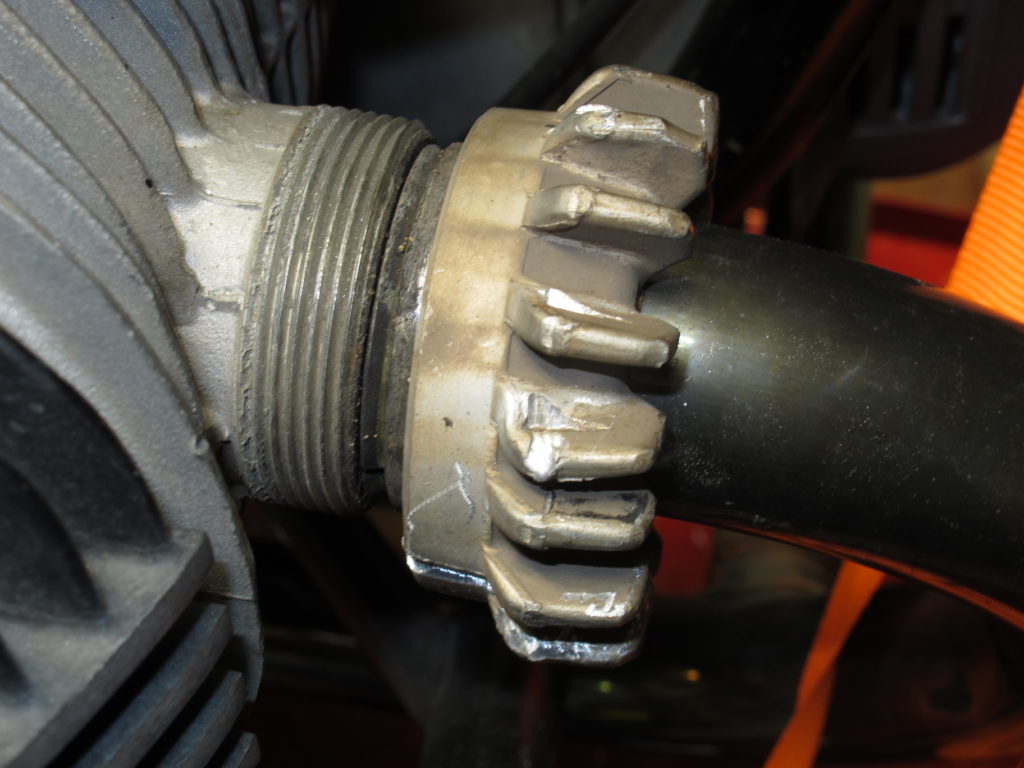

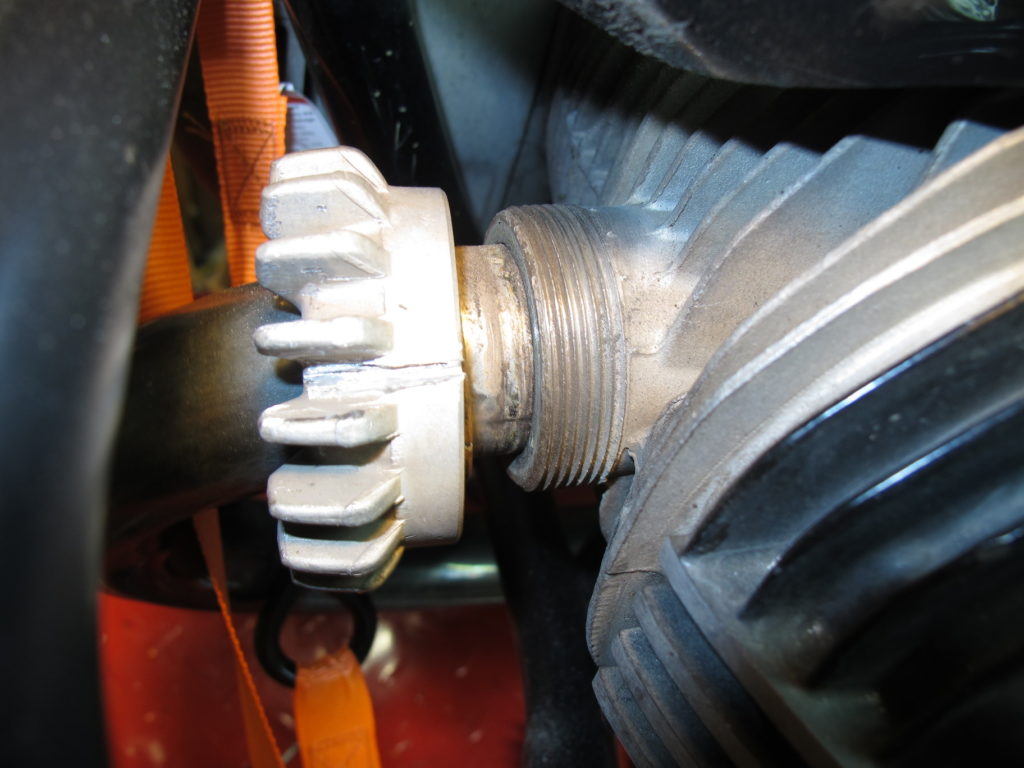

As the right-side nut was already pretty mangled from someone else’s attempt to remove the nut without a proper wrench, I decided to cut that one off rather than risk thread damage. Various sources suggest cutting or drilling to 4mm depth and then splitting the nut with a cold chisel. I didn’t cut quite that deep, though I now believe that is a safe depth. As a result I didn’t manage to split the nut, but in my attempts, I finally saw the nut move. It then came off easily using the wrench. The good news is that the threads look great!

The left-side nut wasn’t visibly damaged like the right, but even with heat and a hammer I wasn’t able to get it loose. Not knowing what conditions the threads were in, I decided against using a breaker bar. So, using a hacksaw blade I again cut down about 3mm, and with a chisel, knocked the nut loose. I still didn’t manage to split the nut, though I probably stretched it a bit as I drove the chisel into the cut. Threads are in great shape here too. In hindsight, I probably could have saved this nut with a bit more leverage on the wrench.

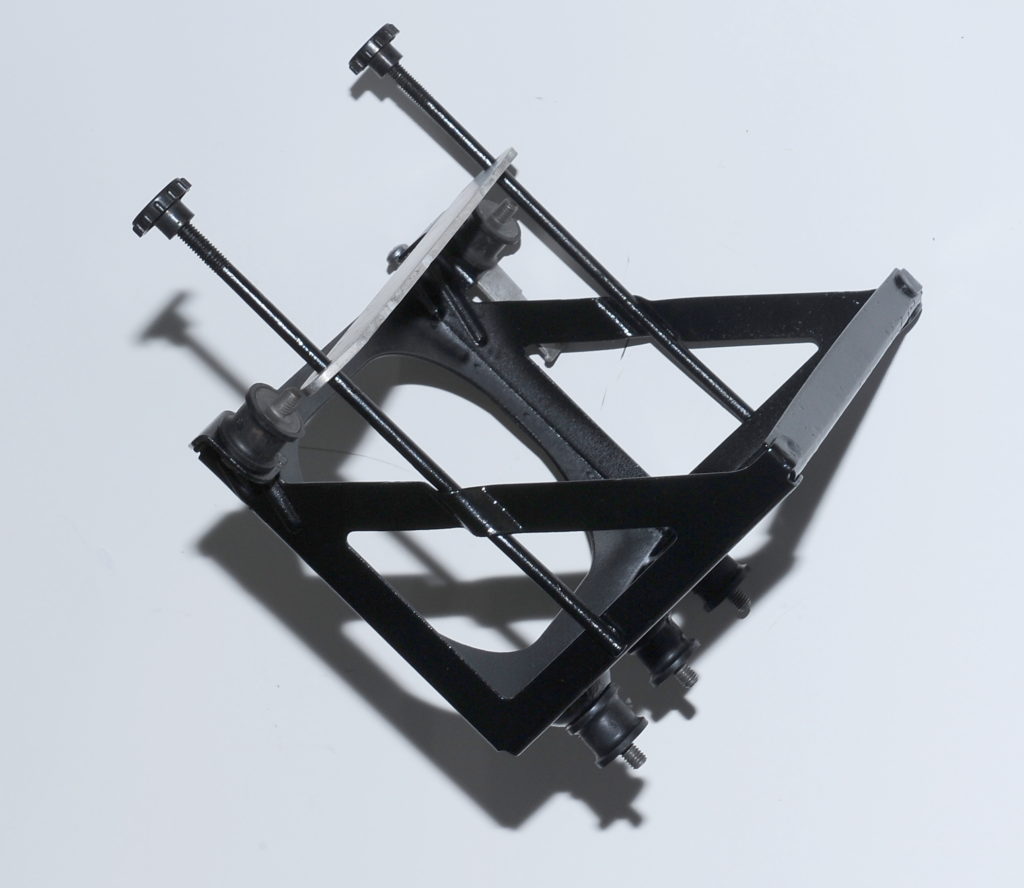

I decided to purchase a used center stand from the same excellent eBay seller that sold me the rear wheel. When the stand arrived I was a bit concerned that it was damaged, not because the foot tab on the left side was broken off, that I could see from Alan’s pictures, I was concerned because it looked as though the the right foot was bent inwards. It turns out that’s normal. After a quick test fit I could see that the foot is bent inwards to avoid hitting the rear brake pedal. It had to be something like that, there just wasn’t any other evidence to suggest that the stand was damaged.

According to Alan’s description, the stand is “from a 1976 R90/6 with 10K miles showing”. I believe that to be correct as there’s only a modest amount of the usual wearing away of the tubing at the bends. There is a bit of surface rust and minor pitting, as you can see.

I picked up some 5/16″ rod at the local hardware store to replace the missing foot tab, which seems to break off of most of these stands; I couldn’t find a used stand with the original tab! As you can see, I’ve already put a bend in the rod. The next steps are to get the stand installed so that I can fit, and then weld on the new rod.

I picked up some 5/16″ rod at the local hardware store to replace the missing foot tab, which seems to break off of most of these stands; I couldn’t find a used stand with the original tab! As you can see, I’ve already put a bend in the rod. The next steps are to get the stand installed so that I can fit, and then weld on the new rod.

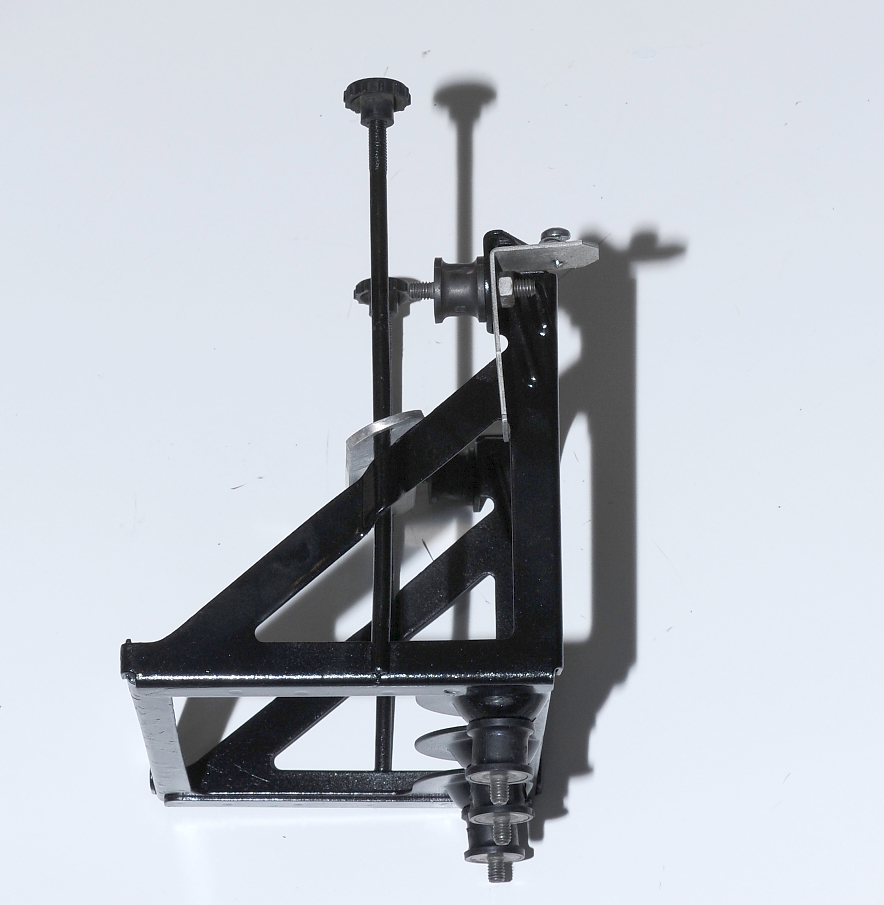

Here’s what a new center stand looks like.

After being able to compare the two stands side-by-side, I’m currently undecided on which one I want to put back on the bike. Here’s how the two center stands compare.