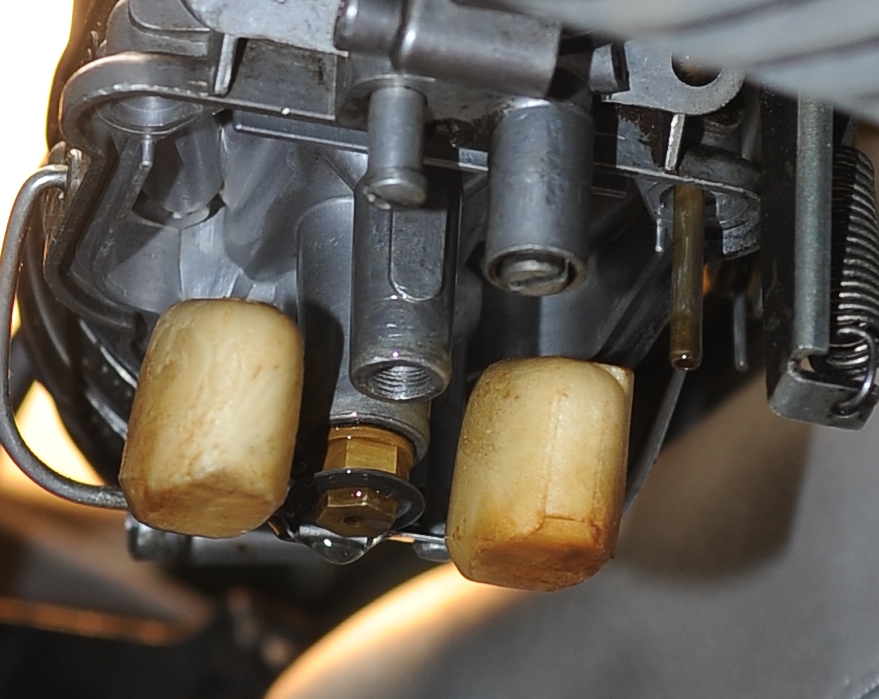

To pull the transmission, I have to first remove the carbs (or at least move them out of the way) and remove the airbox. After seeing the crud floating around in the bowels and the discoloration on the floats I decided to drain the carbs and remove them. I’ll rebuild them before putting them back on the bike. As you can see, they aren’t super bad, but they do need cleaning.

The discolored floats probably indicate that the floats are heavier than the should be, so they’ll be replaced.

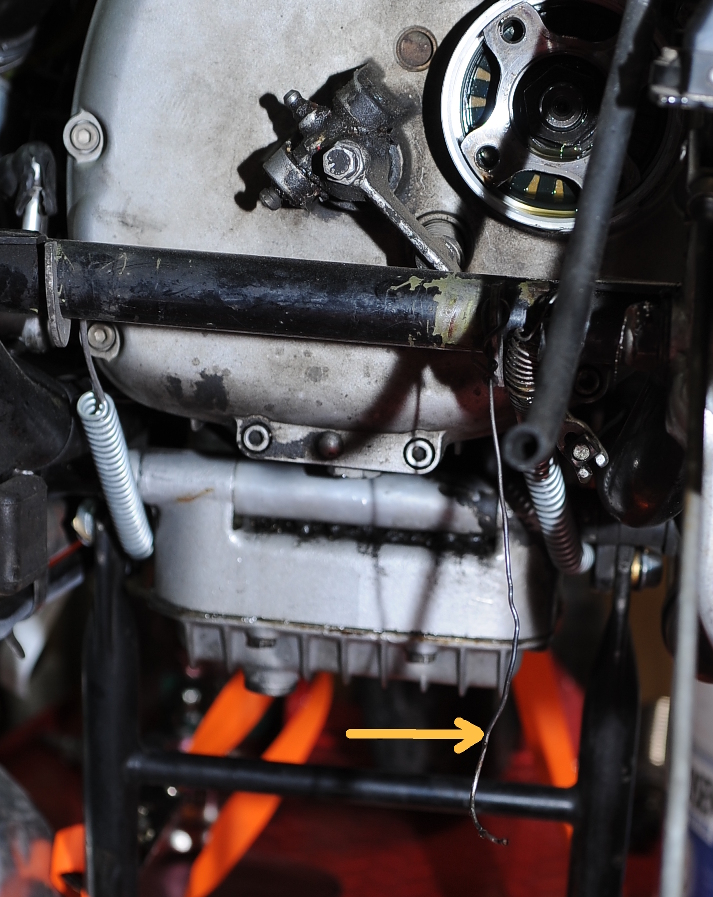

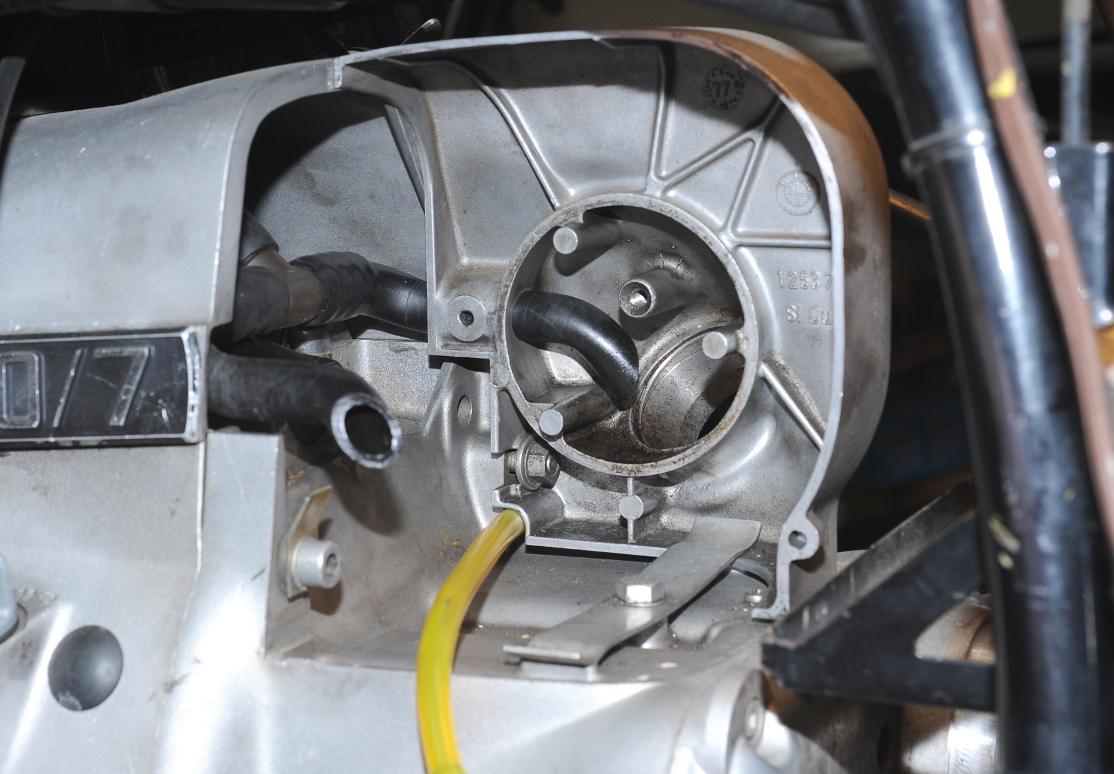

Now here’s a bit of German engineering (not!) If you look at the airbox right cover, you’ll notice that the cover is held in place by a spring on the bottom, and a bolt on the bottom left corner. It looks like you should be able to loosen the nut and slide the cover off. But look at the crankcase ventilation hose, it runs through the case and against the starter cover, effectively preventing you from sliding the case off. I had to completely remove the nut so that I could slide the cover back, and off the hose before I could remove it. That turned out to be OK though as that’s one of the four bolts securing the transmission to the engine; I had to remove it anyway.

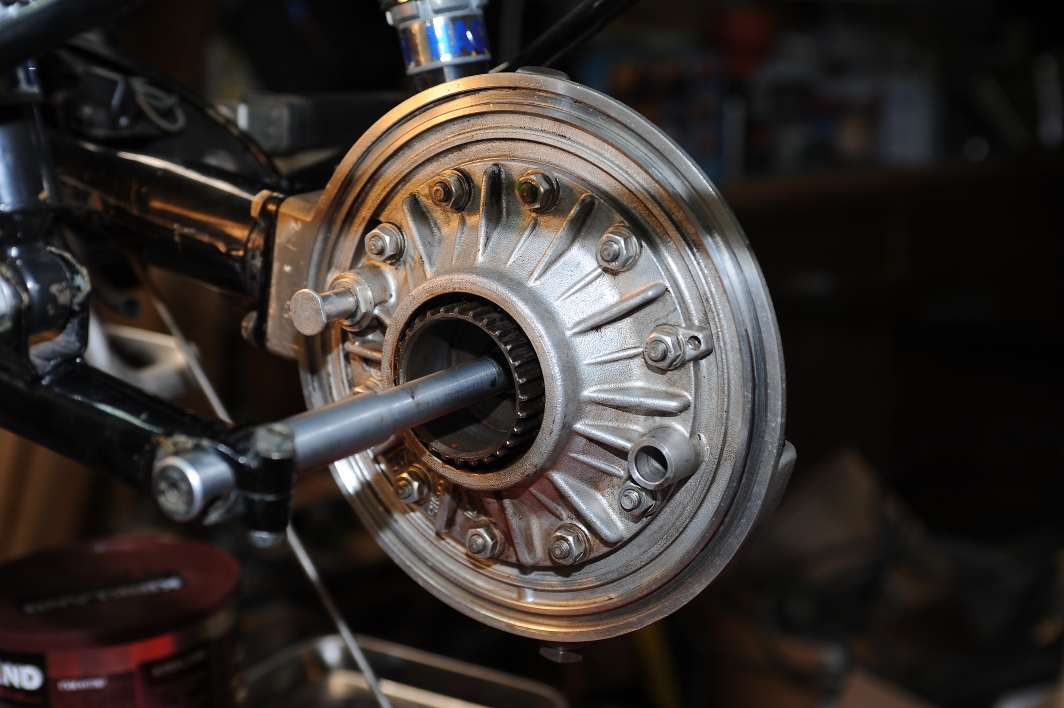

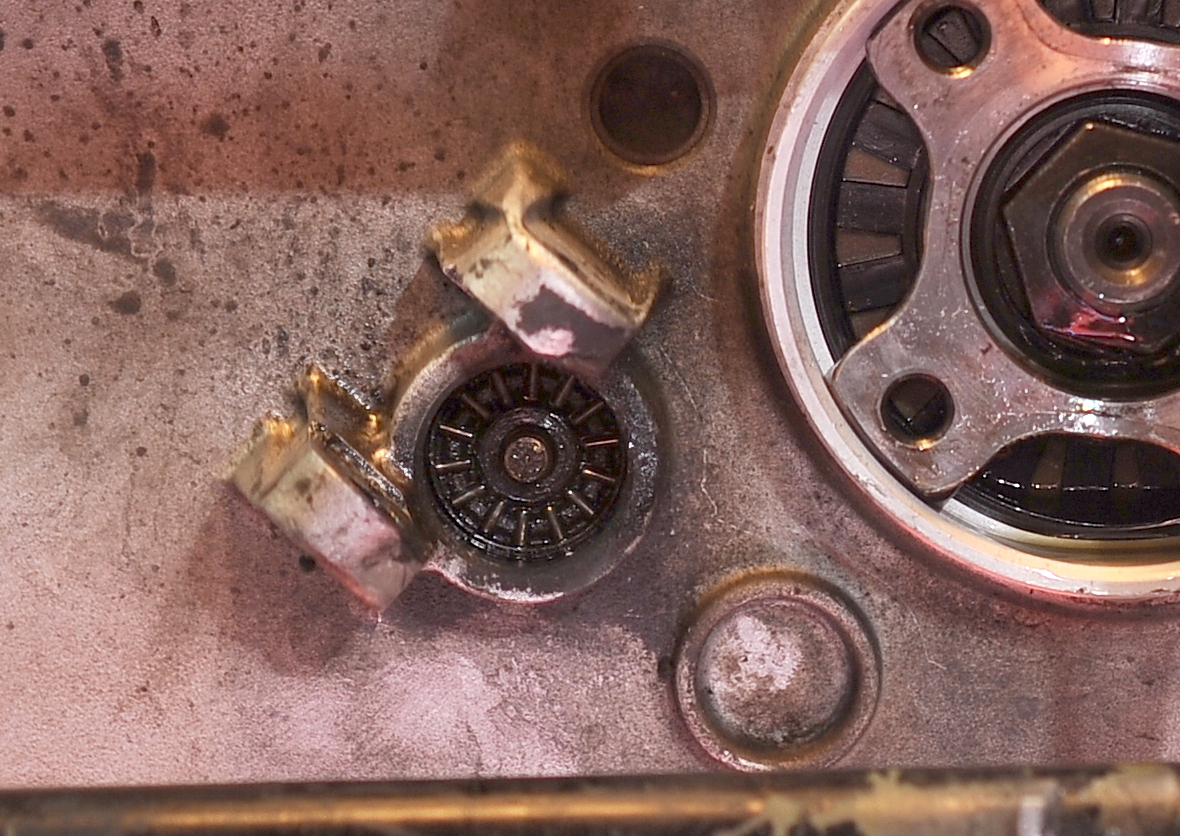

This is the clutch bearing and pushrod with the clutch lever and associated parts removed.

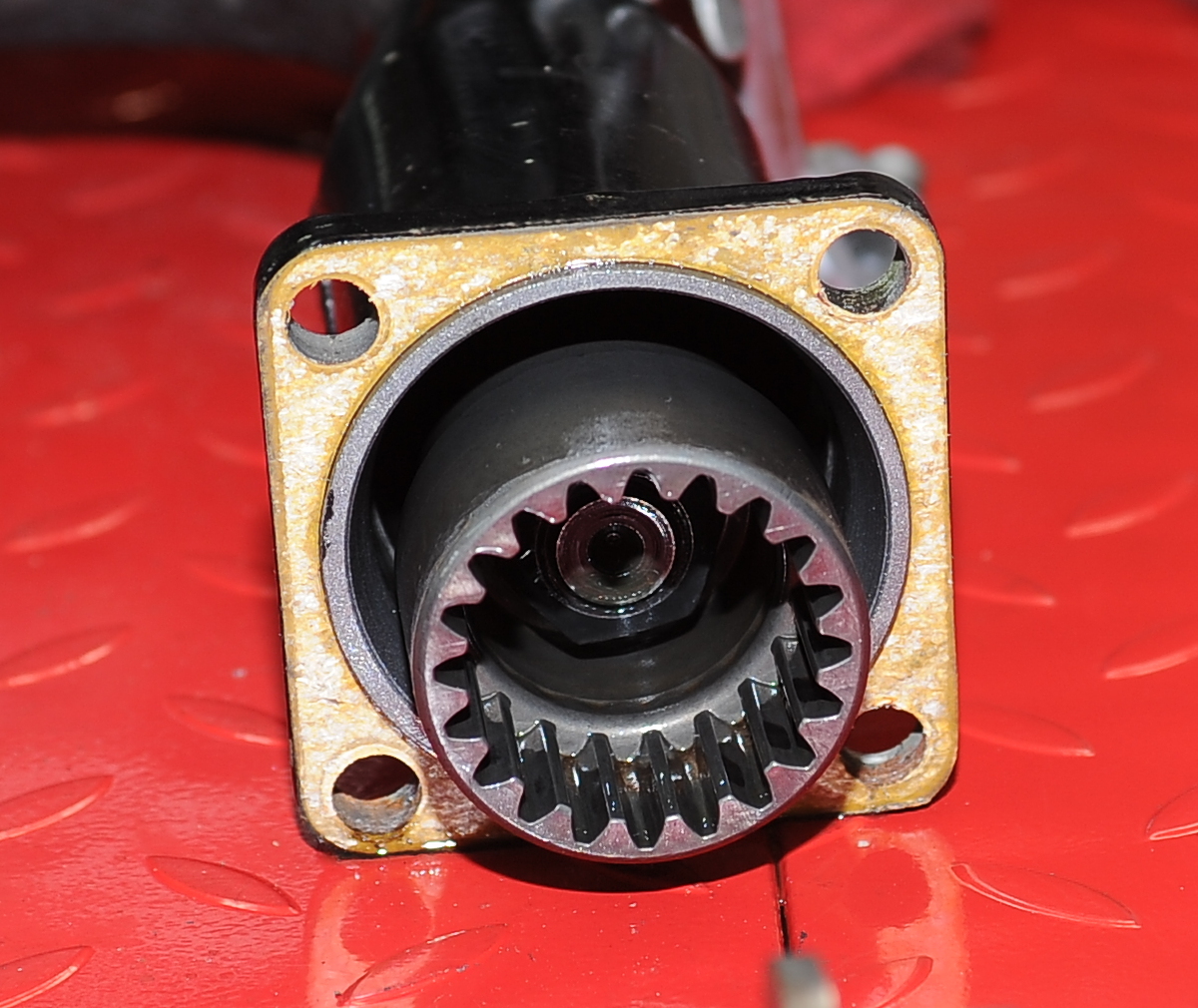

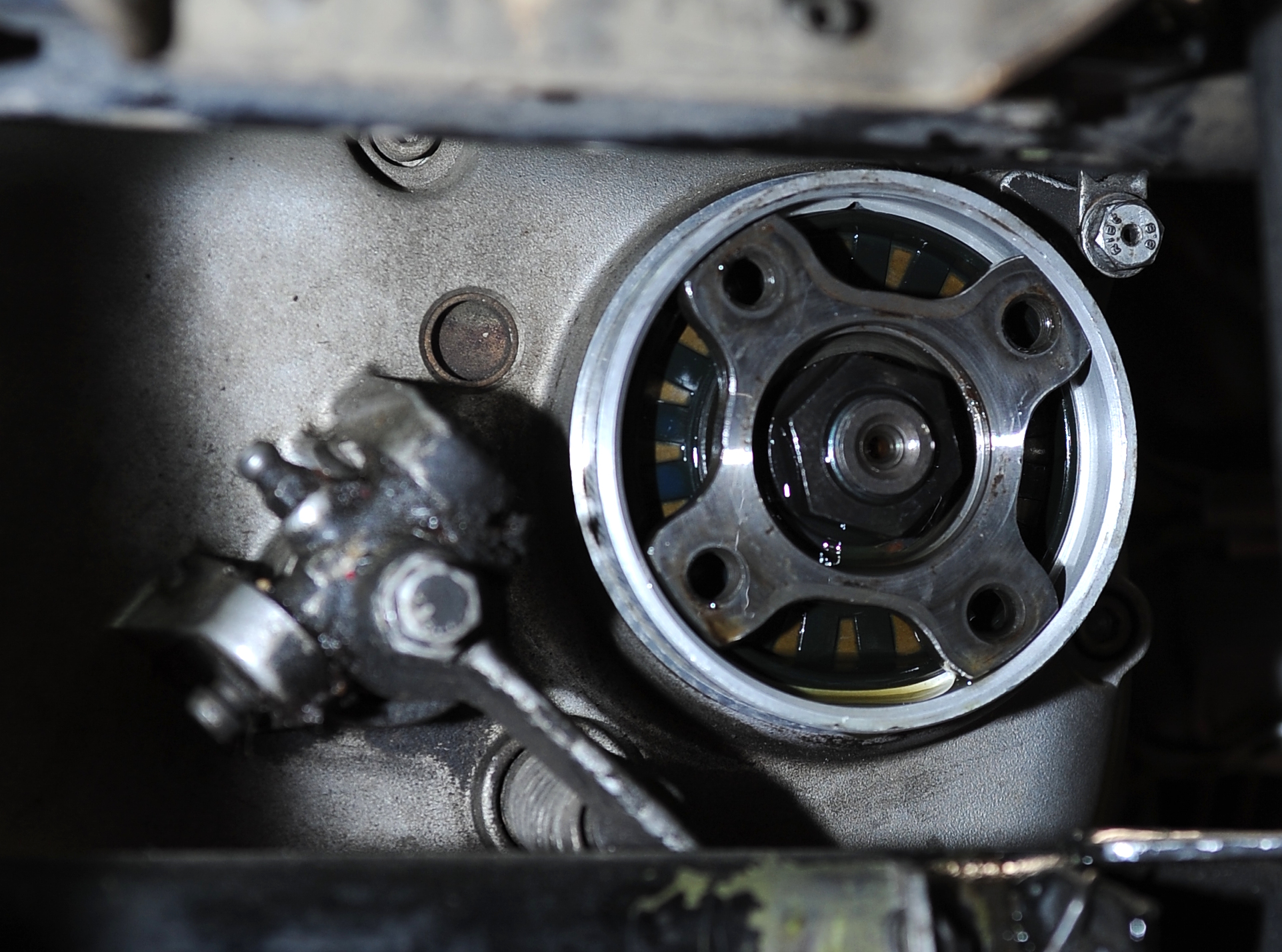

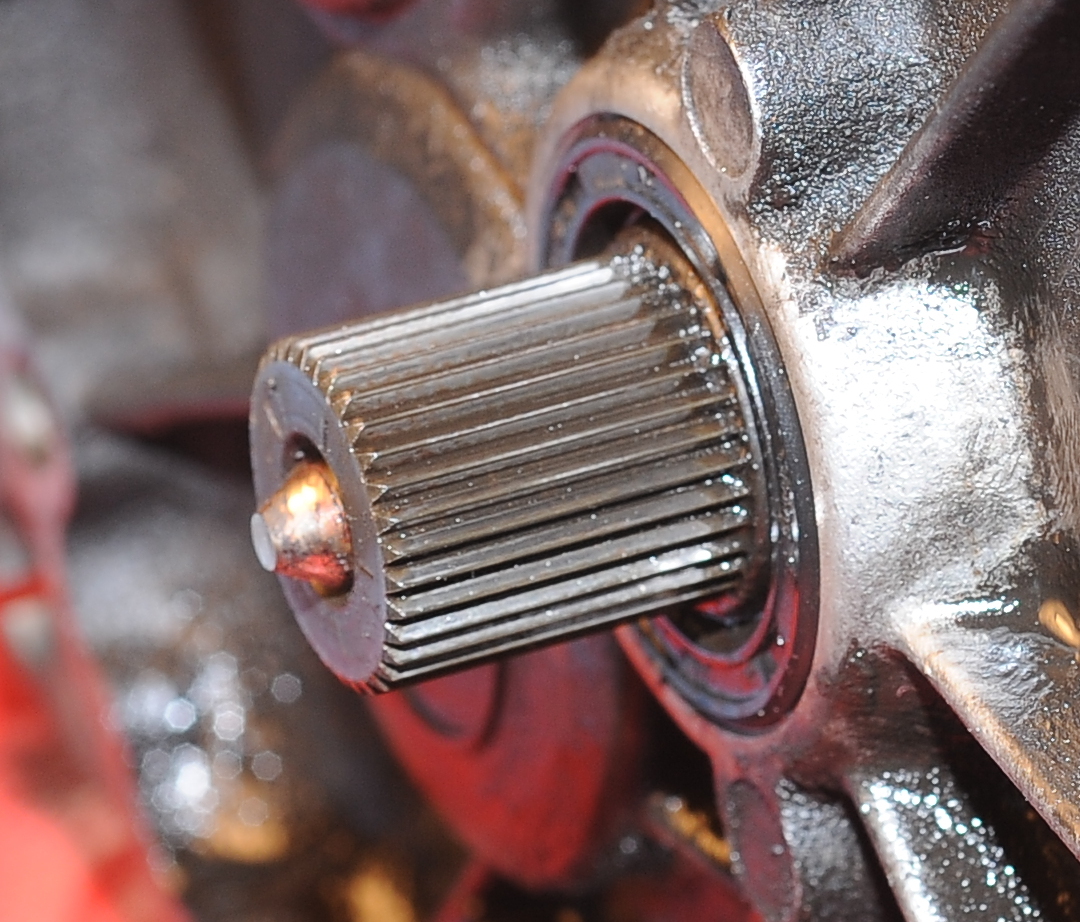

The transmission is only held to the engine with four easy-to-remove bolts. It came out very easy, but only after I removed the top two nuts holding the battery tray, which allowed the battery tray to tilt back slightly giving me more room to slide the tranny out the left side of the bike. Here it is. It looks like the input shaft seal is leaking, so that will get replaced.

The bottom of the transmission is dirty, but looks to be in good shape. Here it’s easy to see the leaky neutral switch. Although, the dirt pattern suggests that the oil might also be from the leaky input shaft seal.

The really good news is that the input shaft splines are in very good condition. Here they are after I cleaned them up a bit. They don’t show any signs of wear or corrosion. The tip of the clutch pushrod looks fine as well.

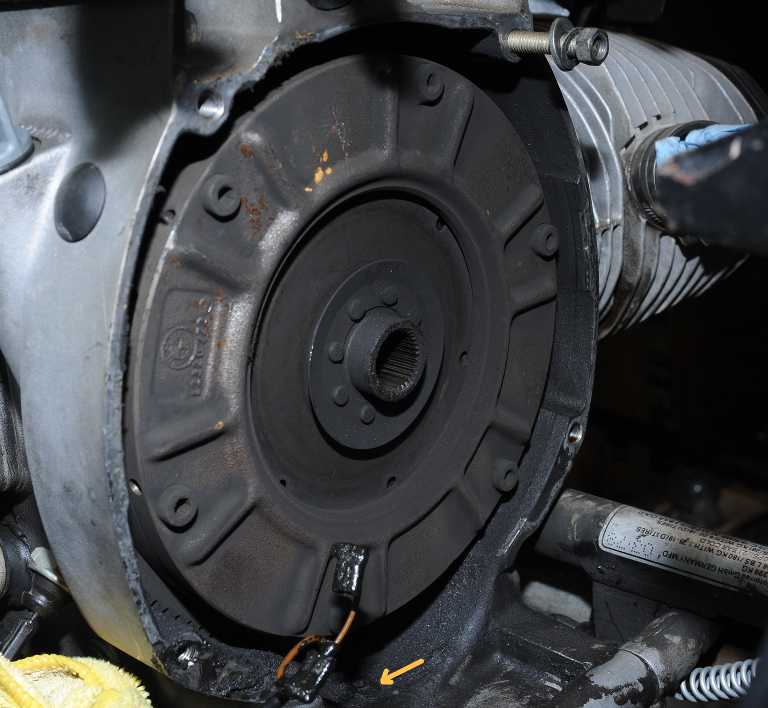

I won’t know the condition of the clutch until I pull it and I don’t yet have the tools I need to do that. While dirty from clutch dust, there’s no evidence that the rear-main seal is leaking. I’ll probably replace it anyway, since I’m pulling the clutch. The arrow points to a loose washer I found at the bottom of the case. It was lightly held in place by the grime. In this picture you can see from the frame tag that the bike was built in March of 1978. I couldn’t see that with the transmission in place.

I found this interesting “mod” today. It looks like someone added a spring to keep one of the center stand springs from rattling. I’ve removed that mod for now, but have kept the spring in case I can’t figure out something better.